رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

2025.1.6 Feed System: The feed system includes a hopper and a vibrating feeder. The hopper receives the raw granite, while the vibrating feeder ensures a steady and controlled

Read More

Granite stone crushing machine can be divided into three categories according to the feed and product particle size: Coarse crusher: from 1500~500mm to 350~100mm; Medium crusher:

Read More

In crushing lines, this product can feed the materials in a continuous and uniform manner to the crushing machine and screen the materials primarily. Materials: Granite, marble, basalt, limestone, quartzite, river pebble, copper ore, iron ore,

Read More

The truckload feeds raw material to grizzly vibrating feeder, over-grid granite feed into the jaw crusher evenly, then to single-cylinder cone crusher, under-grid material conveys to 1st vibrating screen.

Read More

The granite crusher can perform multiple chamber feed crushing. The crushed raw materials are very uniform, and the equipment is very suitable for treating high hardness rock, which can

Read More

1. Feeding Put the granite crushed stone into the jaw crusher with a vibrating feeder, and put it into the jaw crusher evenly to prevent clogging. 2. Coarse Crushing The jaw crusher roughly crushes the granite for a while, the input

Read More

Introduce how to crush granite, whole granite crushing plant flow layout (with photo), and related rock crusher machine. Contact us to do free flow design.

Read More

2021.9.22 The granite (or basalt) crushing production line with an hourly output of 600~700t, according to the configuration plan described above, can be equipped with

Read More

Granite crusher is easy to feed and easy to maintain. Time: 2019-01-22. Granite crushers are used in a wide range of industries, including mining, smelting and metallurgy, railway construction, water conservancy projects and chemical and chemical industries, all of which require the use of this equipment, granite crushers.

Read More

2016.1.1 The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width. The common crusher types, sizes and their performance are summarised in Table 4.1.Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW.

Read More

2025.1.7 The customer purchase this crusher plant for his mining project. Here are advantage of jaw crusher and spring cone crusher: 1.Advantage of the PE500750 Jaw Crusher: Feed opening size: 750mm x 500mm, suitable for the primary crushing of various large material stones, like granite, limestone, river stone and so on.

Read More

2021.12.1 For granite crusher, recommend jaw crusher, cone crusher, mobile crusher, these are suitable for granite crusher, its capacity is strong, high efficiency. Skip to content. ... which can control the feed amount according to the need, in

Read More

2023.1.4 The manufacturing process of jaw crusher is also relatively mature in China and abroad, so in the field of coarse crushing, jaw crusher is the most commonly used granite stone crushing machine. Advantages: simple structure, reliable operation, light self-weight, cheap price, various models, small overall dimensions, large size of feed inlet (up to 1m), simple

Read More

The Stedman Grand-Slam secondary impact crushers are built to handle thousands of materials, ores, and chemicals in wet and dry applications.The crushing action of the Grand-Slam HSI delivers properly sized material the first time through.

Read More

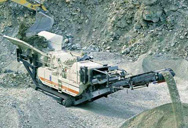

Comprehensive Crushing: This plant usually includes a combination of granite jaw crusher, cone crusher, impact crusher, and vibrating screen.This setup allows for comprehensive processing of granite, from large chunks to fine aggregate. High Efficiency: By combining different types of granite crushers, the plant can achieve a high degree of crushing efficiency and produce 5-180

Read More

A crusher jaw or a gyratory crusher is commonly used as the primary crusher for granite crushing. Before your selection, consider factors such as the feed size, capacity, and adjustable range of the crusher. APJ-5075E crusher jaw Choose cone crusher for medium and fine/secondary crushing. Next, cone crusher for medium and fine crushing (5-31.5mm).

Read More

4 天之前 Granite crushers can be divided into three categories according to the size of feed and product:. Coarse crusher: crush from 1500~500mm to 350~100mm; Medium crusher: crush from 350~100mm to 100~40mm; Fine

Read More

2021.11.19 1. Granite sand making equipment: Jaw crusher. Applicable feed size: ≤ 1200mm, jaw crusher is needed when granite raw material>300mm. Discharge range: 10-300mm (according to the feed ratio) Production capacity: 1-1000t/h, the specific model can be consulted online. Production advantages: For the coarse crushing of granite, jaw crusher must be ...

Read More

Aimix Group is a professional crusher manufacturer, we can provide you with customized stone crushing solutions. Skip to content. Menu. Home; ... such as limestone, granite, basalt, iron ore, river pebble, quartz stone, copper ore, construction waste, etc. Production capacity. 5-800t/h. Feed particle size. ≤1020 mm. Power. 15-250kw. Cone Crusher.

Read More

Small stone crusher which is manufactured by fote heavy machinery is also named as mini stone crusher. FTM small stone crusher is mainly applied to crush materials with small hardness, such as bricks, refractory material, glass, gypsum, limestone, coal, slag, etc. Small stone crusher can also be used in the experimental process and geological research.

Read More

Granite Crushing Sand Making Washing Processing. The truckload feeds raw material to grizzly vibrating feeder, over-grid granite feed into the jaw crusher evenly, then to single-cylinder cone crusher, under-grid material conveys to 1st vibrating screen.

Read More

To choose a suitable crusher, you’ll need to provide information about the material you plan to crush. The abrasiveness and hardness of the material determine the compressive strength it can withstand before breaking. The size of the feed material to determine the size of

Read More

APF-V Series Impact Crushers for Sale in Indonesia. APF-V series impact crusher can deal with materials with feeding size less than 500mm and compressive resistance not more than 350 Mpa despite the large, middle or small size hard materials (granite, limestone, concrete, and other non-metallic minerals).This machine is widely used in mining, highway and railway, construction

Read More

2025.1.17 High quality Granite Crushing Equipment Jaw Crusher Machine 14600KG With 500mm Feed Size from China, China's leading Jaw Crusher product, with strict quality control Jaw Crusher factories, producing high quality Jaw Crusher products. vr. Chongqing Sanming Heavy Industry Co., Ltd ...

Read More

2024.7.19 Hardness is a key factor in choosing the appropriate stone crusher, as different stones naturally have different hardness levels. Hard stones, such as granite and basalt, usually require powerful jaw crushers and cone crushers for effective crushing. The crushing process for some softer rocks is simpler, as they require less crushing force.

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.